SuperCurl Desk at Commercial New York Office

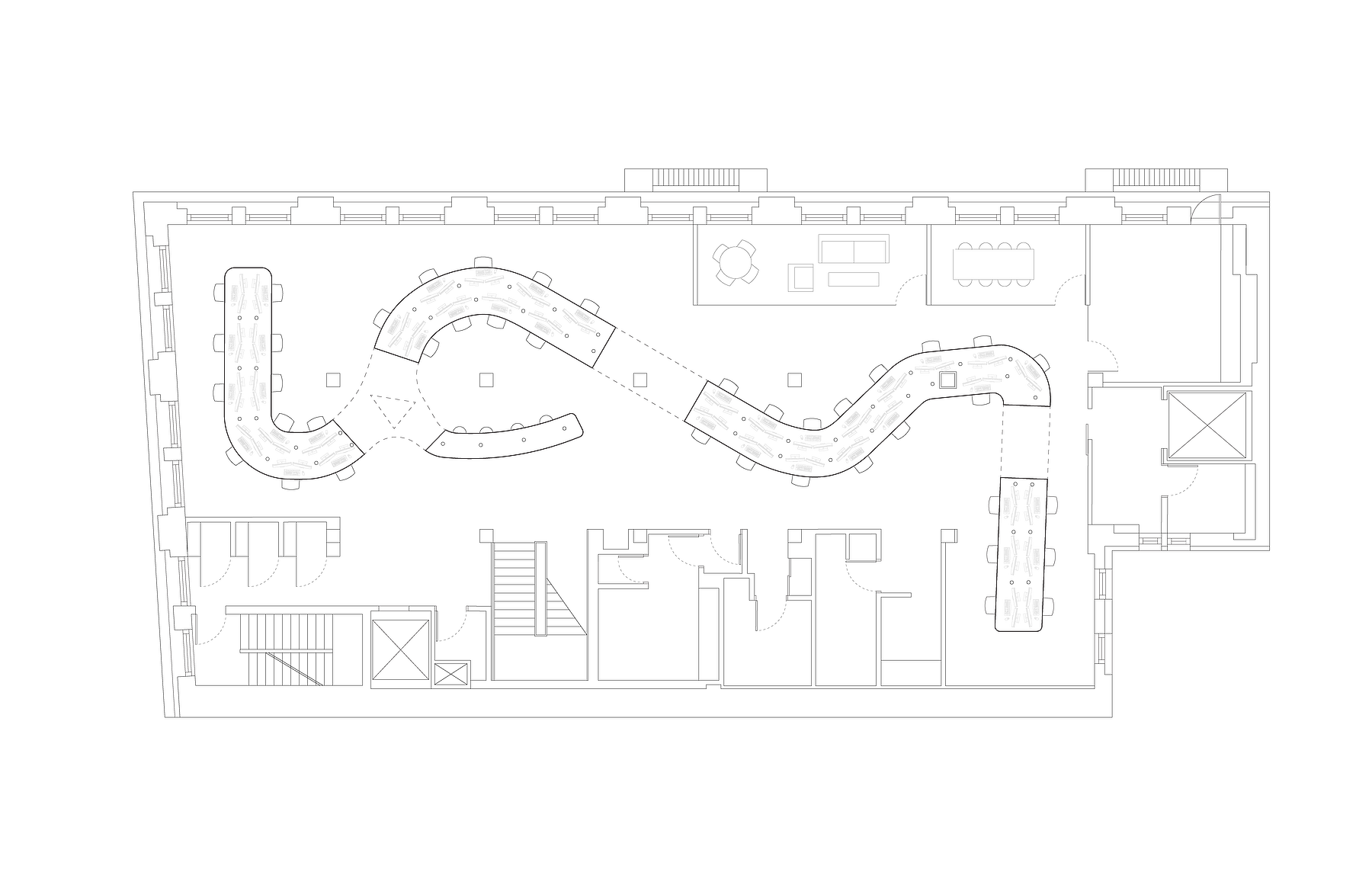

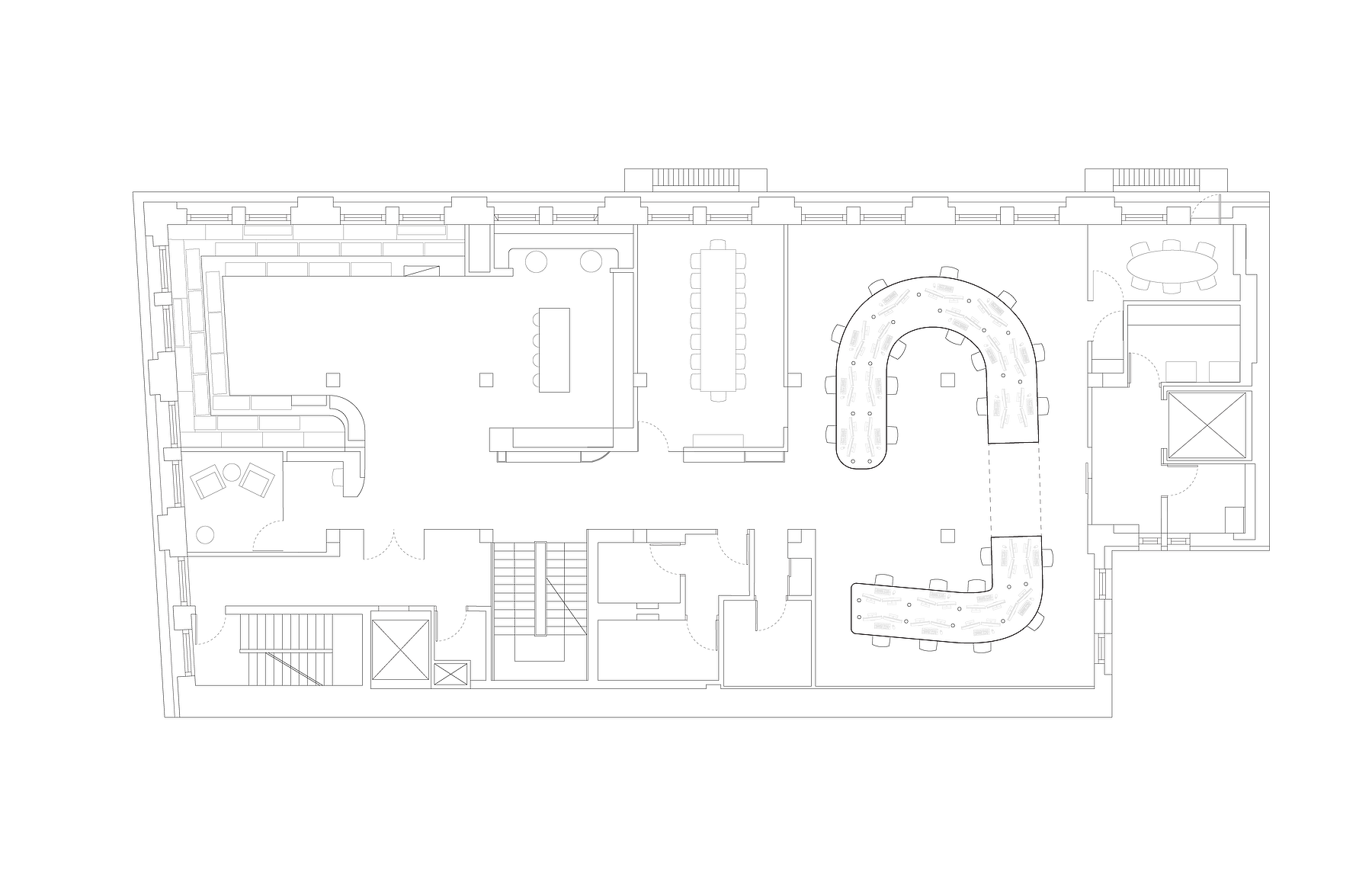

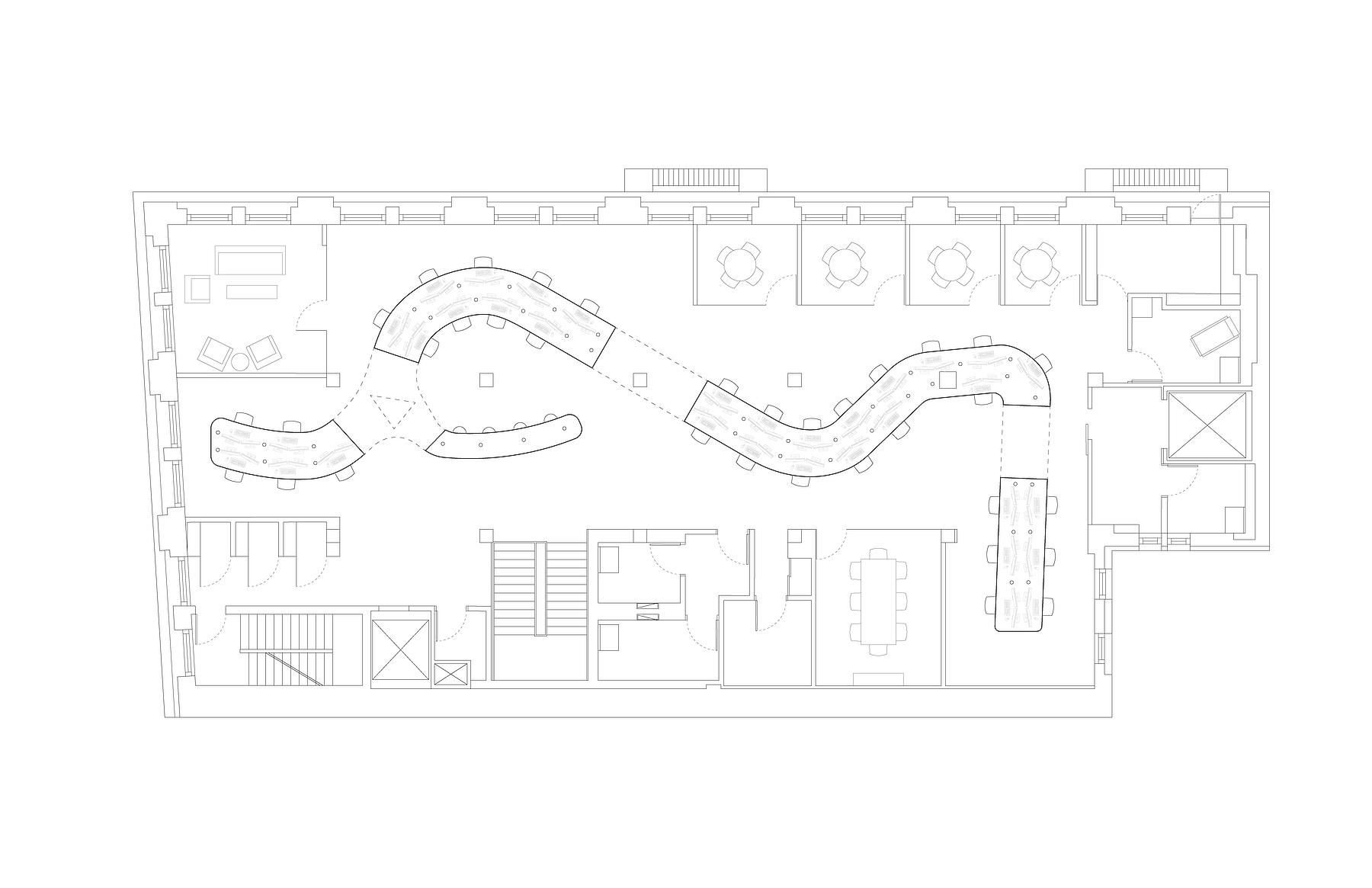

By leveraging our thermoforming and CNC millwork capabilities, we fabricated and installed a seamless sculptural workspace, titled the SuperCurl desk, designed by Gary Shoemaker Architects PC for a multistoried commercial Manhattan office. The system is envisioned to encourage an engaging and non-hierarchical seating arrangement to allow for cross-team collaboration and communication.

Client

Private Client

Architect

Gary Shoemaker Architects PC

Location

New York, NY

Completion

2020

Photography

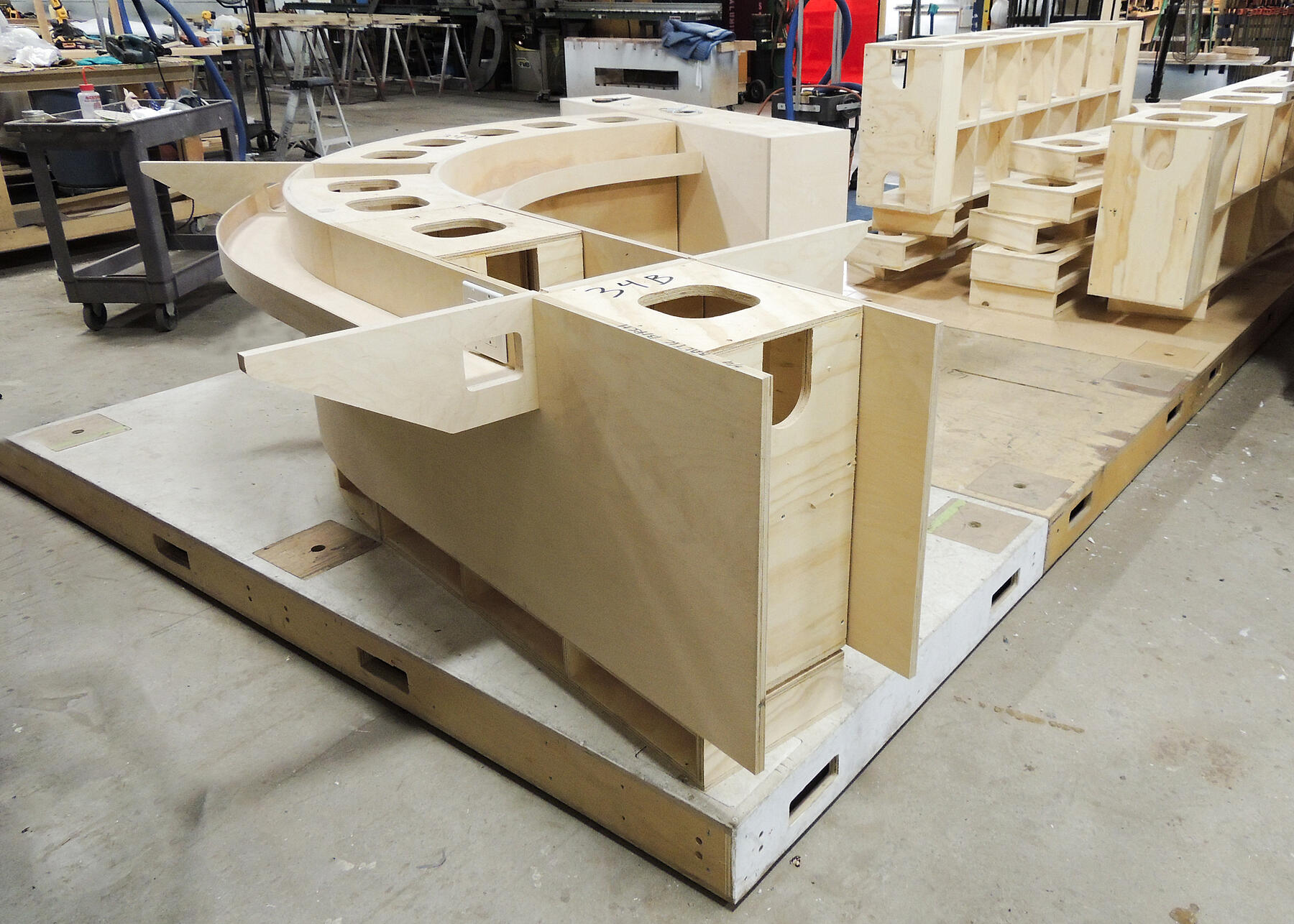

Beginning with a Design Assist that took the form of a full scale mockup, our project management team collaborated with the architect to refine the office system for fabrication and installation feasibility. The most prominent feature of this custom workspace is the seamless Avonite solid surface work surface that meanders through the office interior. Our CNC team milled the outlines of each piece while our fabrication specialists glued, seamed and thermoformed unique conditions throughout the project. Table edge and reveal conditions between sections were delicately seamed and sanded on site to achieve the unified design intent.

In order to enhance the natural flow of this communal work area, we fabricated large archways that allow convenient access while continuing the seamless solid surface ribbon throughout the space. To maximize the utility of these archways, we detailed each with upholstered seating and open cabinetry for storage, as designed by the architect.

As a balanced contrast to the bold aesthetic of the solid surface, our team fabricated the exposed baltic birch plywood substructure and casework. We retained the distinct plywood edge quality, which enhanced the linearity of this large statement workspace. Using digital fabrication and traditional carpentry techniques, our team built curved plywood modules in sections to accommodate site access to the multiple floors that the office occupies. Our CNC capabilities were integral to cut these modular structures to accurately achieve such a dynamic design.

Installation required both patience and finesse, as each module needed to accurately align with one another to create a consistent flat surface that could be successfully assembled and seamed. Our project management team carefully detailed the sections to coordinate with the existing base building columns and scope by other trades.

With engaged design engineering and seasoned fabrication capabilities, our team realized The Curl’s striking design through challenging fabrication conditions and complicated site conditions.