Elevator Lobby at 55 Hudson Yards

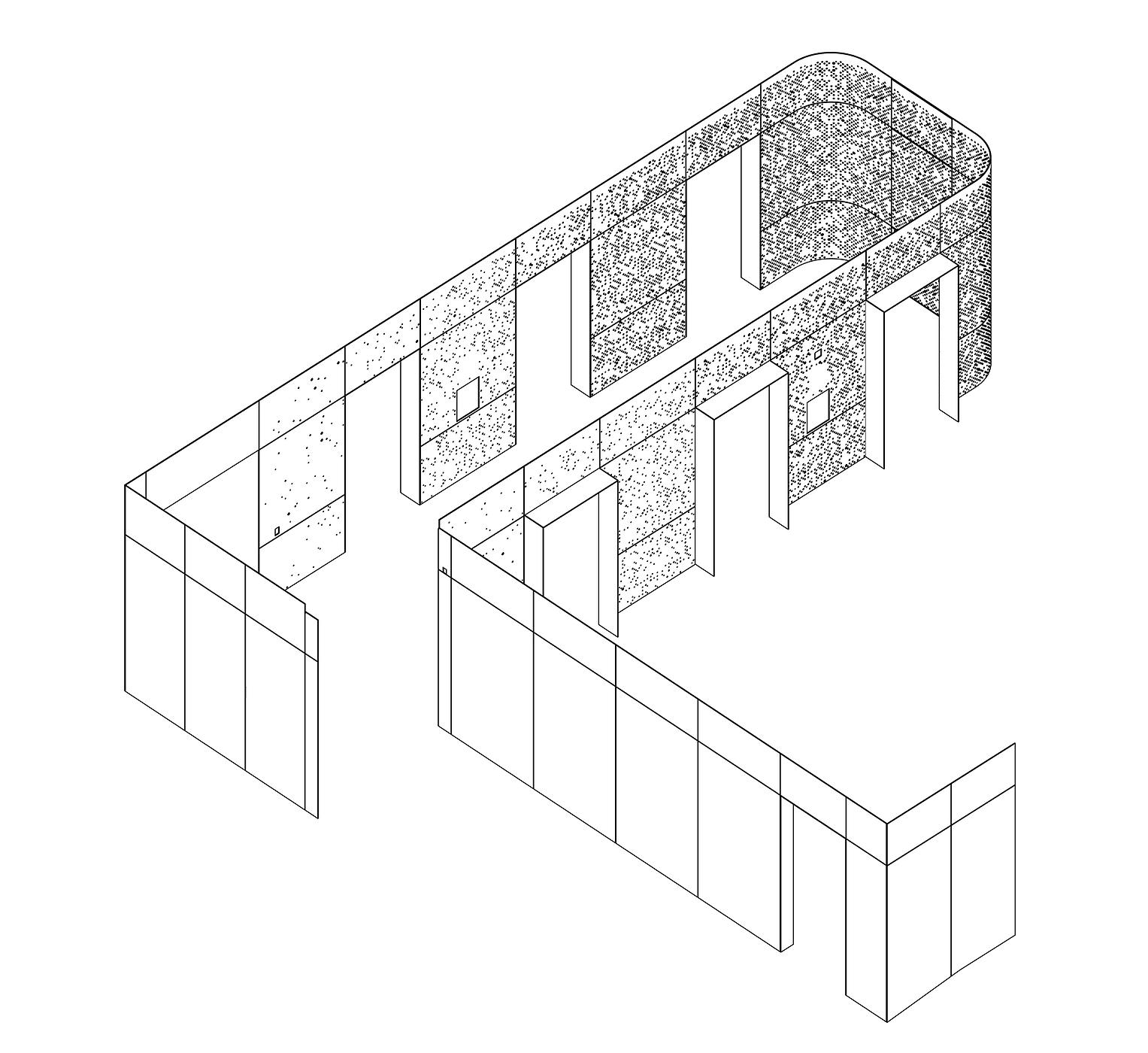

Multiple fabrication techniques and finishes were brought together to create this illuminated entry space for a private office at Hudson Yards. Designed by Architecture + Information (A+I), this project is unified by a rich gradient of backlit metal textures that wraps around a curved elevator lobby, leading to an open reception area.

In addition to fabricating more than 1,000 sq ft of complex aluminum millwork, we used a series of different surfacing techniques to develop a unique finish that complements the project’s integrated lighting.

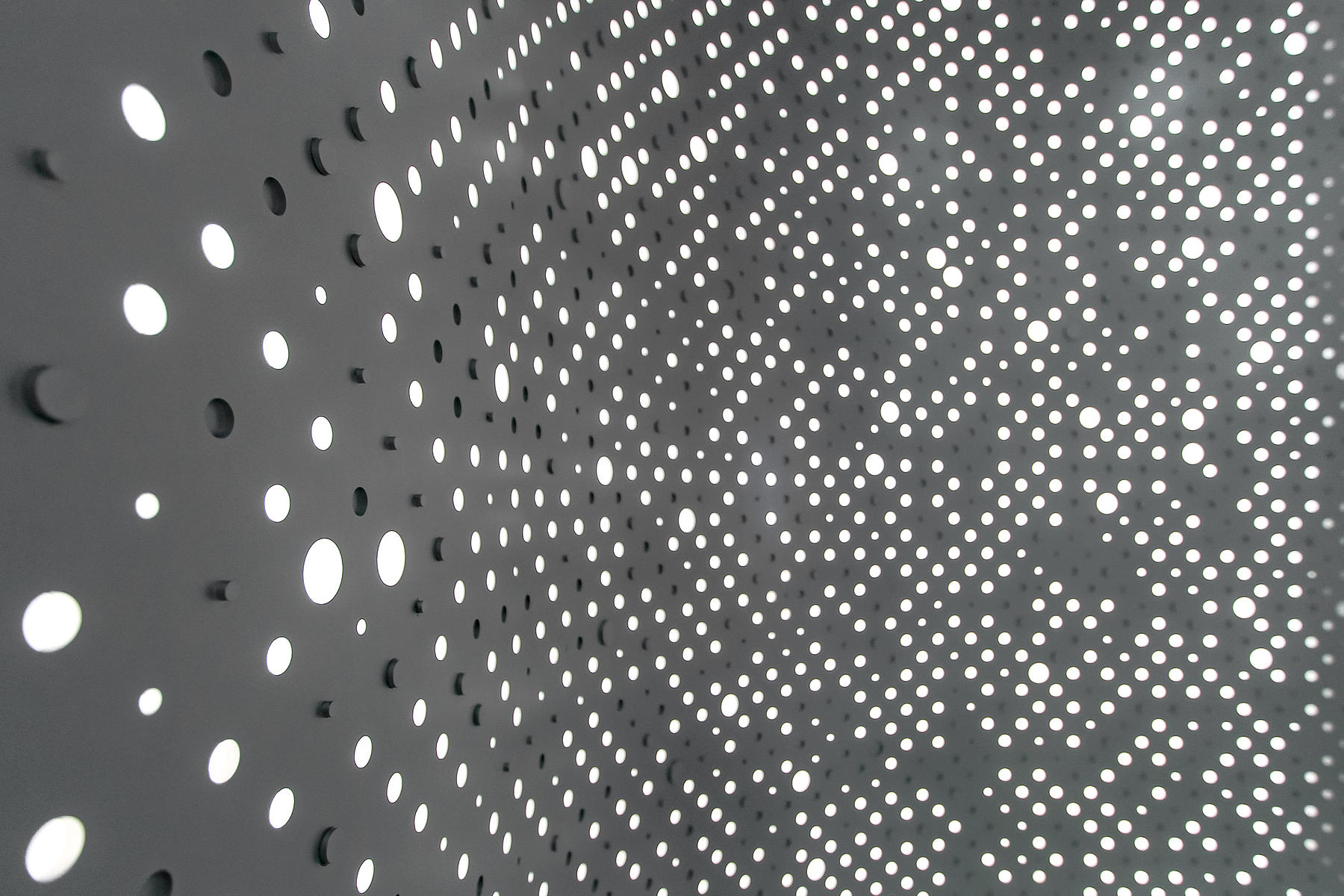

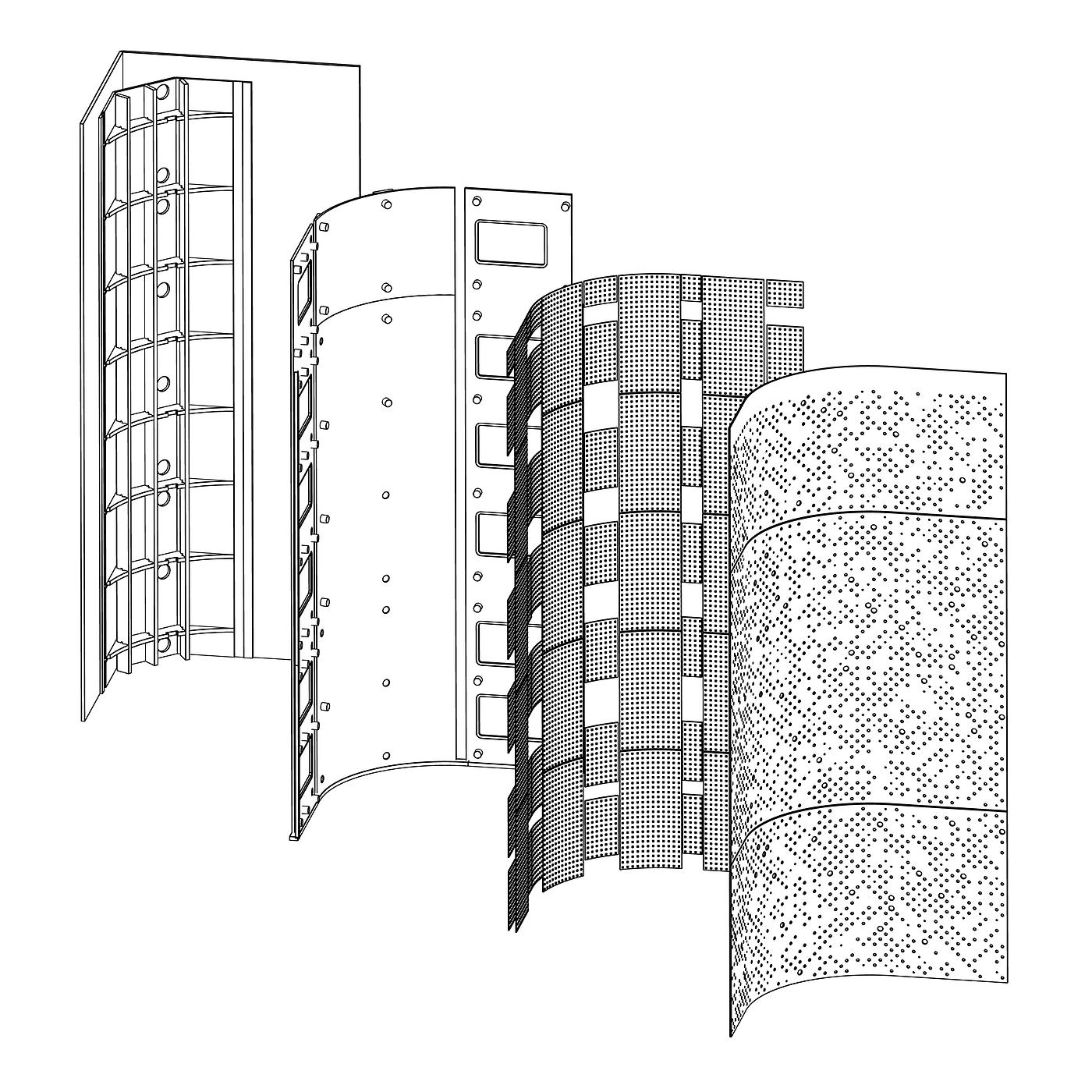

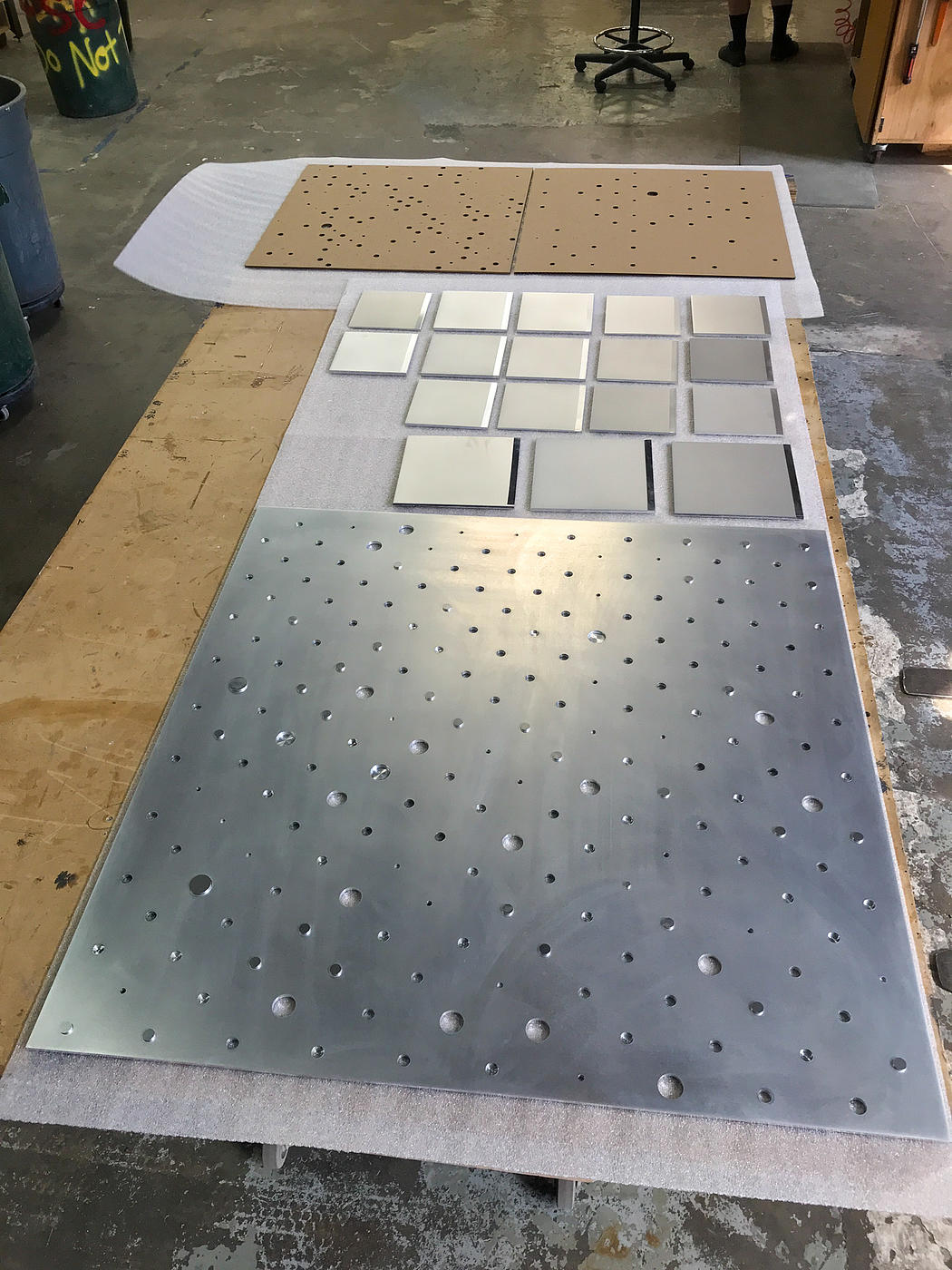

Our process started with the gradient pattern running throughout the design. Variations in size, relief and density were used to parametrically control the pattern’s gradation—which becomes concentrated in the center and more dispersed towards the outer panels. Initial mockups allowed us to test the visual quality of embossed, debossed and perforated details. We then CNC-milled those three types of relief details across each surface, using variations in diameter to achieve an overall natural-looking randomization.

Behind the metal panels, a layered lighting system shines through the perforated surfaces. LED sheets provide an even light source which is then diffused through an added layer of translucent acrylic. One of the design challenges was to avoid unintentional fluctuations in the brightness that can occur where panels meet, near structural connections or around small features like the elevator call buttons. To mitigate this, we interspersed small puck-like standoffs between layers that support the panels more discreetly than linear connections.

The designers specified a uniform and lustrous finish to enhance illumination throughout the space. Working through a series of finish samples, we arrived at a three-part approach. We started by fabricating all components from mirror-finished aluminum, which was crucial for maintaining a consistent appearance during subsequent phases. Each part was then bead-blasted to give them a sense of depth and a rough, but even, sheen. Finally, we coated the completed panels with a clear protective film to prevent the accumulation of handprints and dirt.

To our team, this project presented an opportunity to bring together multiple areas of expertise and experimentation, from materiality to integrated lighting and multiple fabrication techniques. For visitors, guests and office staff, the elevator lobby frames the first part of a welcoming entry experience.