Cafe Table at 30 Hudson Yards

Building a 20-ft-long table for a cafe amenity at Hudson Yards required a specialized blend of digital and artisanal techniques, as well as creative design engineering that goes beyond what’s typical for projects this scale.

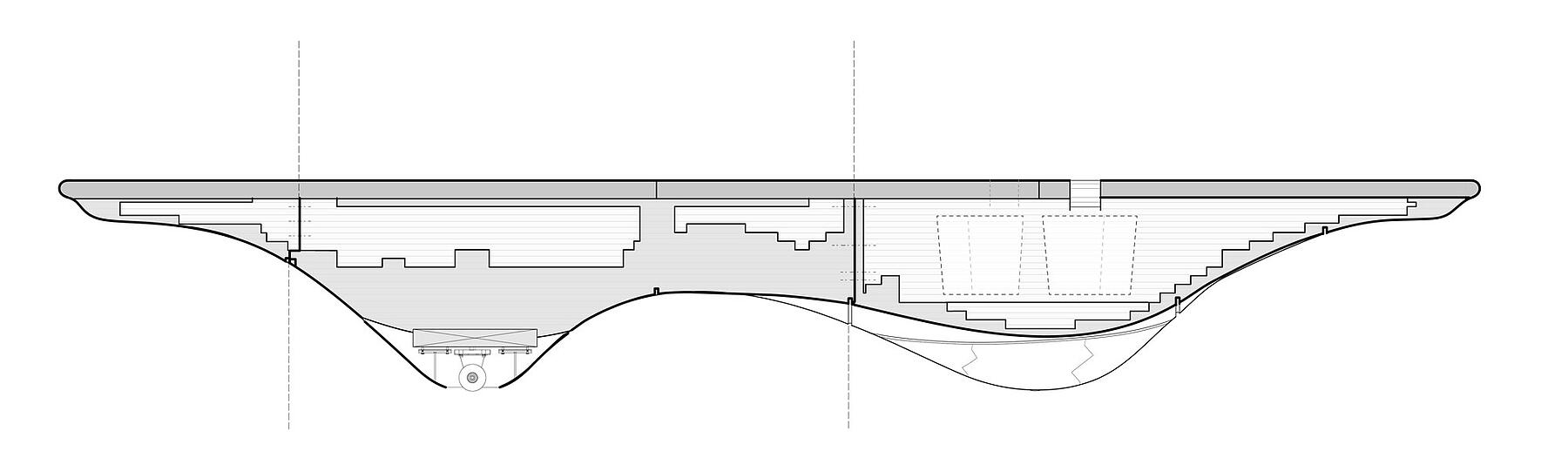

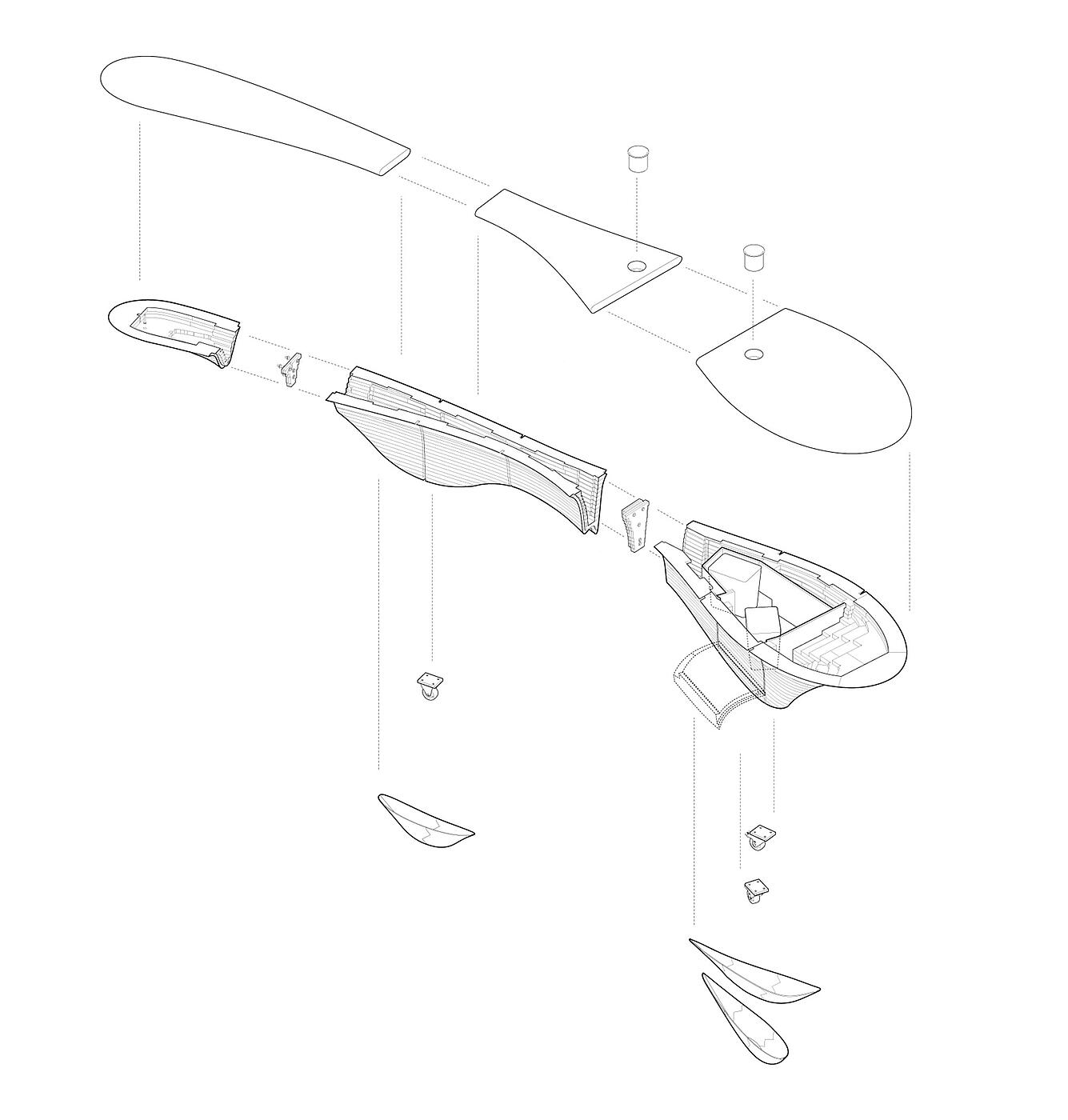

Architects at KPF brought us on for a second-phase addition to their cafe amenity in Hudson Yards, which included a large curving table that runs the length of the storefront and complements its “draping” millwork. The tabletop is milled from stack-laminated Corian, while the body is made from solid walnut paneling laid over a laminated walnut and plywood frame. Each of its three drooping legs are supported by casters shrouded in bronze covers. While not as large or overtly complex as some of our architectural-scale projects, this design posed numerous technical challenges that made this project particularly exciting for our team.

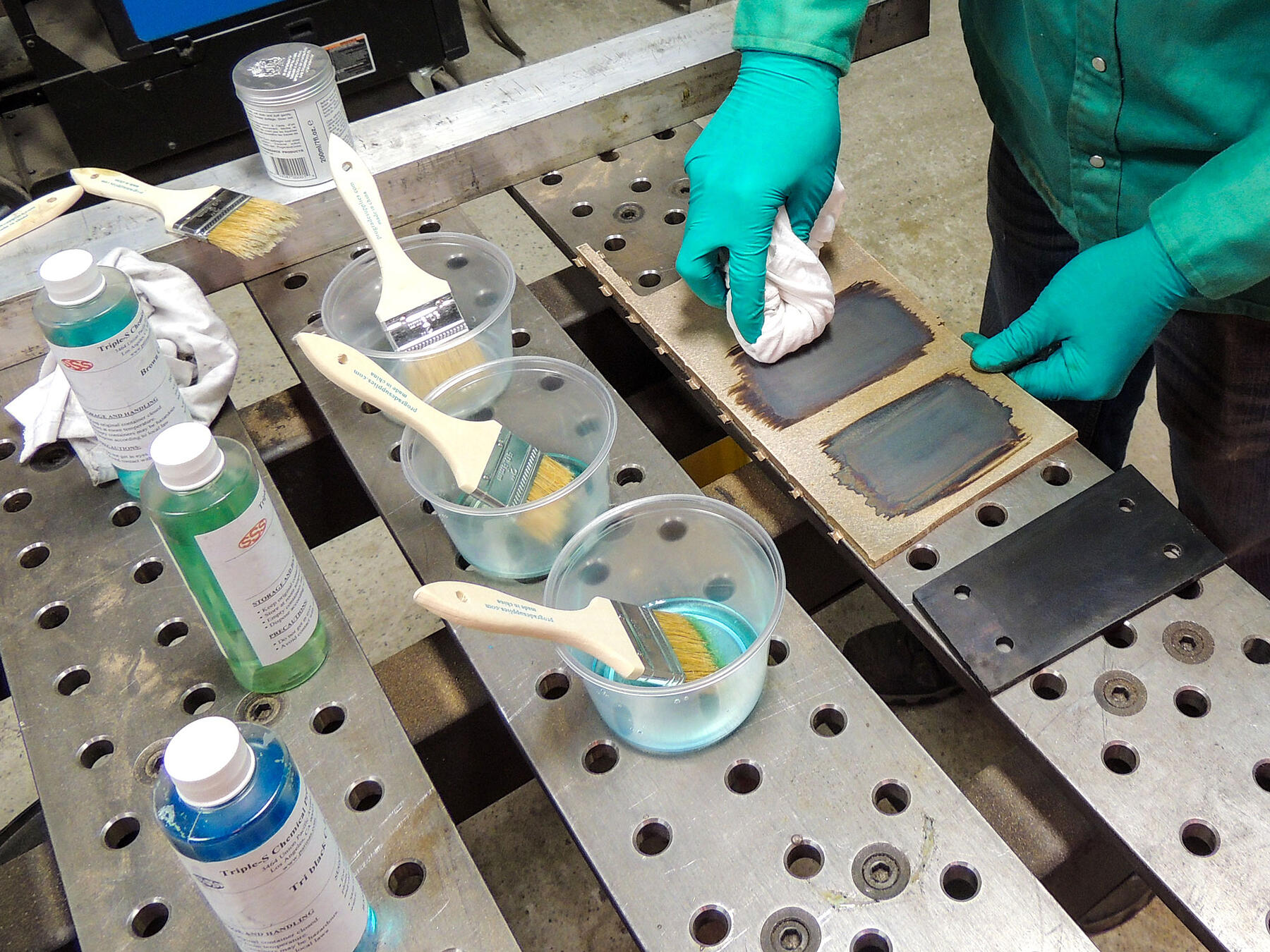

Before beginning the initial design engineering phase, we had to ensure we could match the existing palette of materials and finishes that were already used on site for the walls and service counter. So our team experimented with different stains, patinas and application processes, and eventually dialed in on a set of techniques that matched the tones and nuance of the earlier millwork and metalwork.

With the finishes resolved, we started on a delegated design process to refine the functional and structural details concealed within the table’s unique form—particularly in regards to structural engineering and minimizing exposed hardware. Integrated within the body of the table, a storage compartment houses waste and recycling bins which need to be serviced throughout the day. By producing mockups of the compartment door and testing alternative designs and hardware, we came up with a fabrication method that was both discreet and easy for staff to use on a regular basis.

At 20 ft long, the client needed an easier way for their team to move and store the table during events or special programs. Responding to that need, we developed a way for the table to be broken up into several smaller pieces that would be more manageable to work with and able to fit within the freight elevators. We laid out bolts and mechanical fasteners in a way that would be simpler for staff and maintenance teams to disassemble and reassemble.

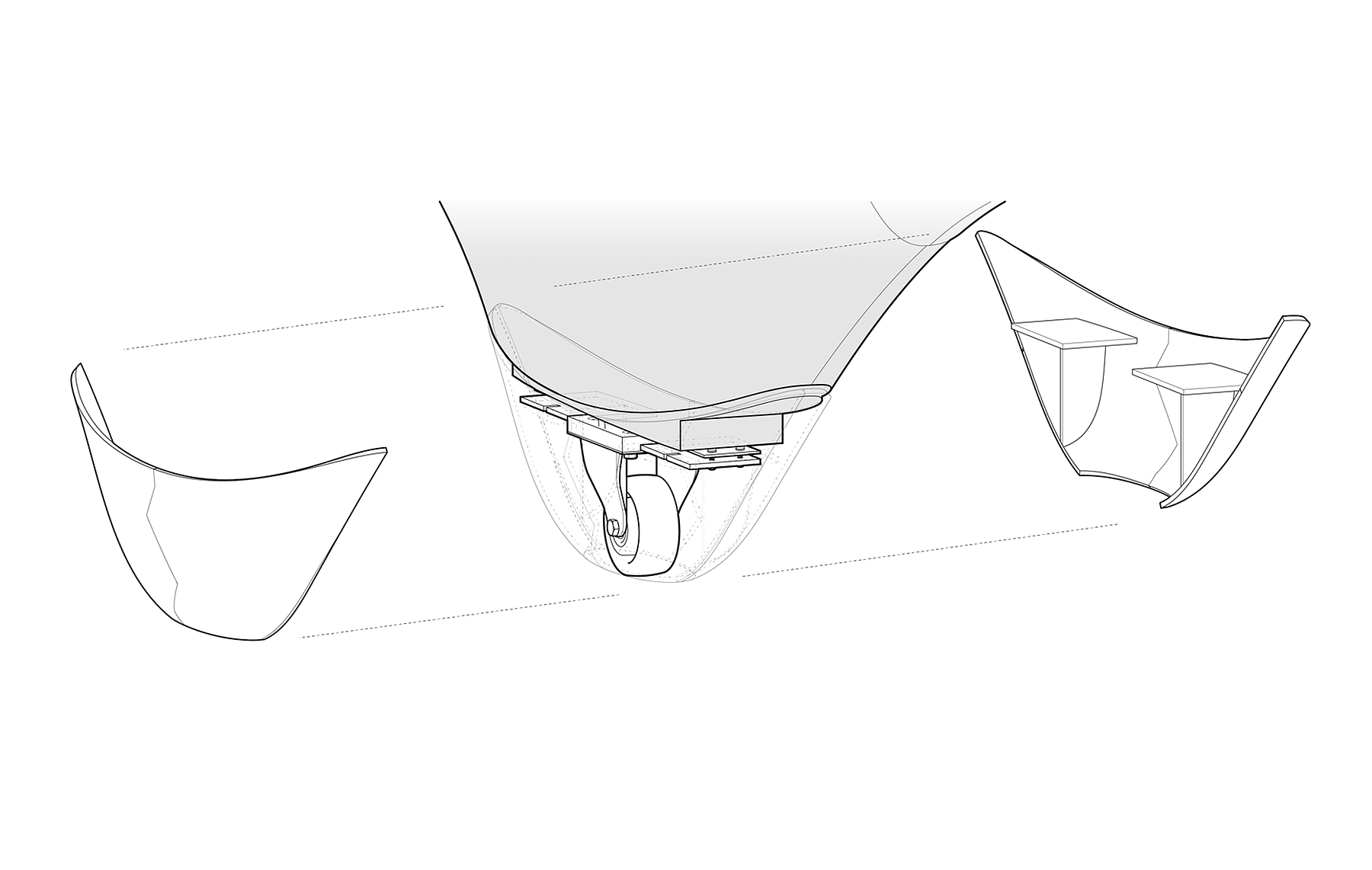

The most specialized components in this system were the custom bronze caster covers. Each table leg is supported by a caster housed in a bronze cover that fits seamlessly with the milled wood section above it. The covers can be removed for easy access and are made from two detachable parts held in place by industrial magnets. The use of metal not only protects the legs against wear, but blended use of distinct materials was an important part of KPF’s design vision.

All-in-all this project represented an exciting opportunity for us to blend multiple skill sets together—from coordinating structural details and testing ergonomic revisions, to blending machining and artisanal techniques. By taking on the project management of all parts of this process we were able to fulfill KPF’s vision for a sculptural cafe setting. And because of the early design engineering phase, servicing this large-scale feature is as easy as possible for the cafe staff.

Client

Architect

Location

New York, NY

Completion

2020