300 Lafayette Lobby

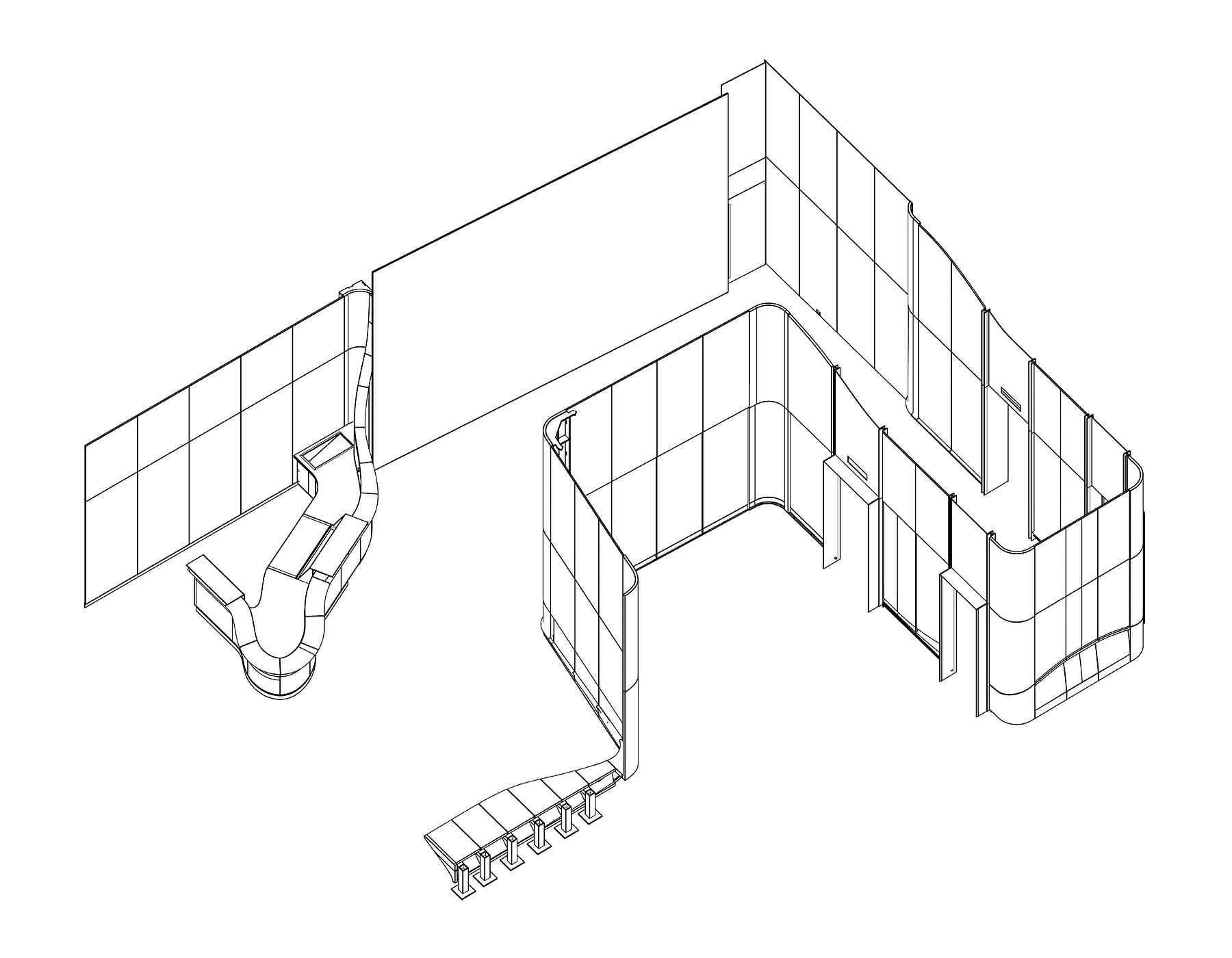

To create the lobby millwork and metalwork at 300 Lafayette, we adapted several tried and tested techniques in new ways—particularly with a vertical application of stack-lamination for the project’s rippled walls and undulating reception desk.

COOKFOX designed a welcoming entry space for the building’s primary workplace tenant, and brought us on to execute their project vision. With two distinct materials at play—blackened steel and solid white oak—the quality of fabrication was critical. Our experience with metal finishing and digital woodworking helped achieve their design intent.

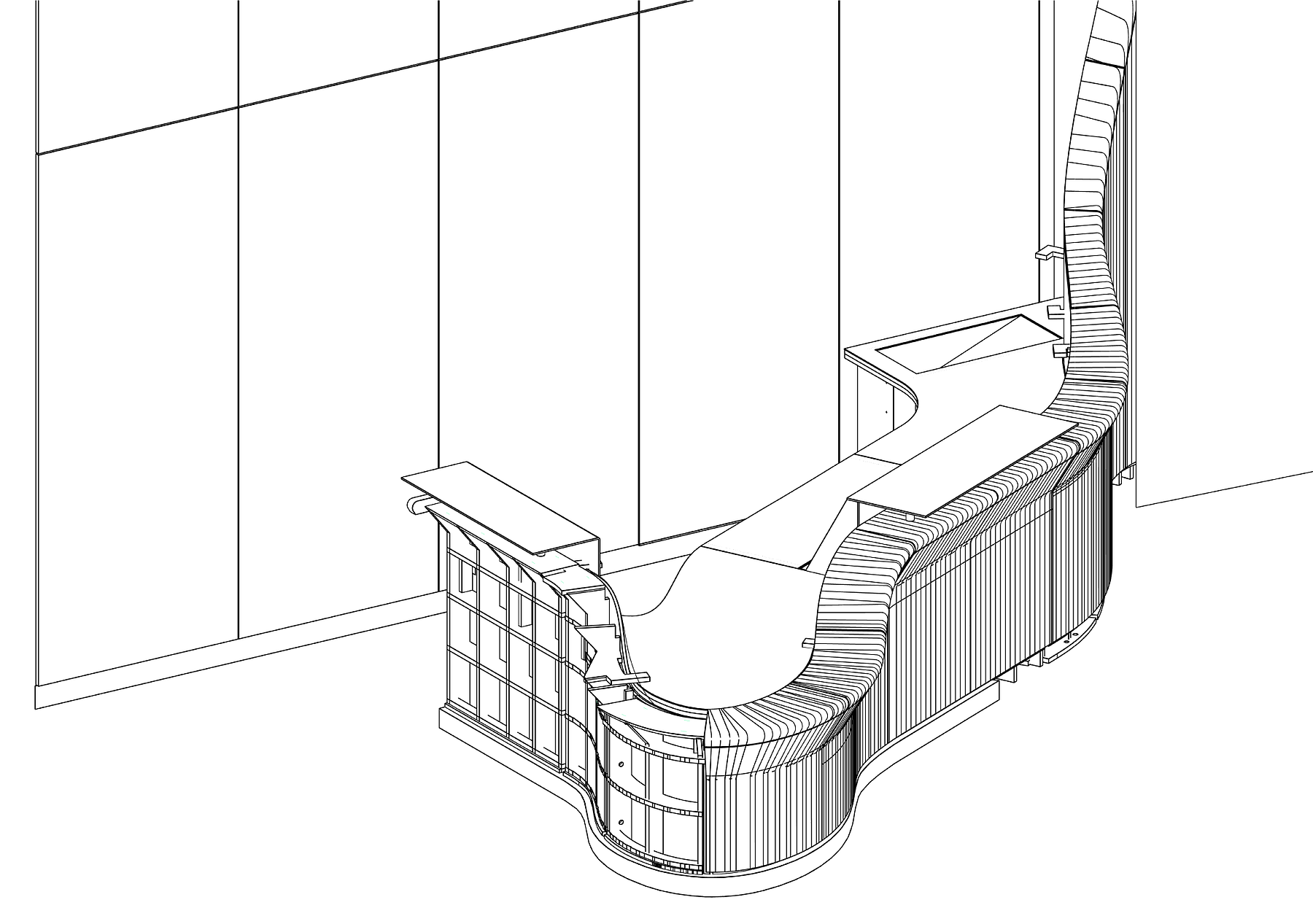

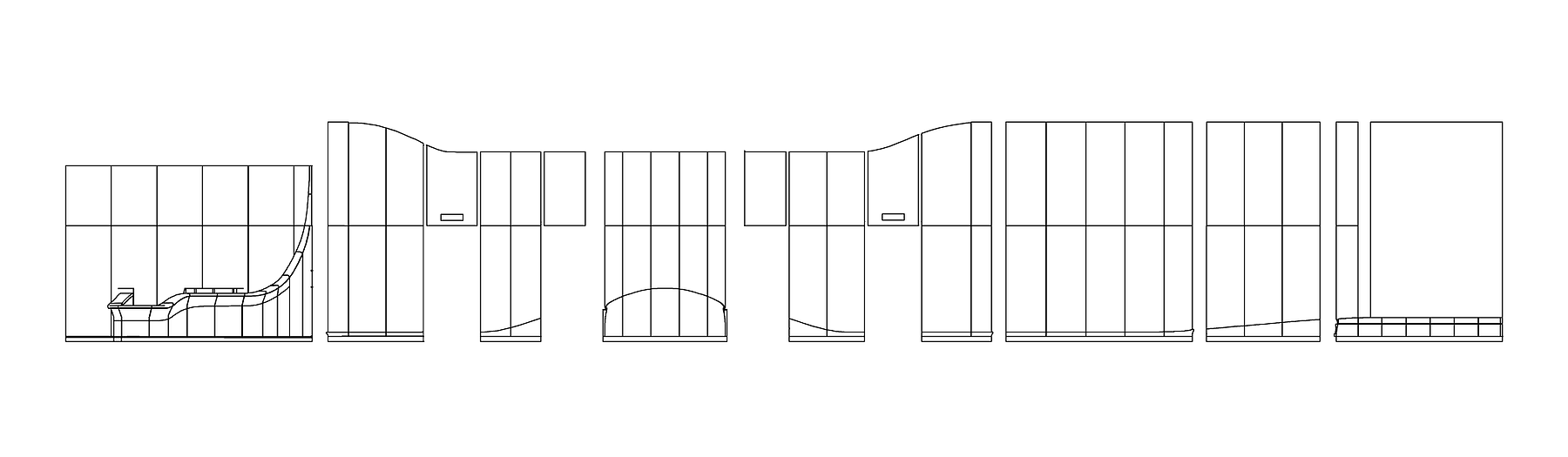

Stack lamination was the best woodworking technique to control for the distinct rift-sawn grain orientation specified throughout this project. Not only do you have more control with solid lumber (compared to veneer or other alternatives) but it’s also more durable, making it well-suited for a high-traffic space like this. To meet the design intent of tall, vertically-oriented boards, we adapted the standard stack-lamination technique, which is typically used in horizontal applications. With a vertical configuration, each board needs additional mitering to fit seamlessly in place. When viewed from the end, each side has a unique angle that needs to be cut precisely, similar to a keystone in an arch. The detailed mitering process also allowed us to control the type of exposed wood grain, keeping the rift-sawn face visible across all the curves. The result is a much taller and cleaner visual effect, complemented by the design’s single ripple that loops around the lobby.

This small, yet dimensional, accent winds around towards the front of the space where it protrudes from a side wall forming a built-in bench. Across from this and at the other end, the same milled detail curves outward to form an undulating reception desk. Our team detailed a removable top surface to the desk which has several benefits: each section is easier to repair or refinish, the smaller board size reduces waste during production and it gives us more control over the grain orientation resulting in a more consistent appearance between the top and sides. Where the desk and wall meet, the tops twist into extremely curved sections that were difficult to keep properly oriented. However, we worked through early mockups to find the best configuration of lumber and added dowels in between to compensate for internal tension.

Other sections of the wall are clad in blackened steel panels, including fire access panels and elevator openings. We developed a custom patination process, and each component was meticulously treated and burnished for an evenly mottled finish. While this process may seem less-involved in comparison to the millwork, our ability to take on both scope areas (as well as installation) allowed us to ensure a higher quality integration of seams and edge details.

Clients

LargaVista Companies; Related Companies

Architect

Location

New York, NY

Completion

2019

Photography

Bruce Damonte, SITU