Fitting Rooms at Forty Five Ten, Hudson Yards

For the New York debut of the multi-brand boutique Forty Five Ten, architects 5G Studio Collaborative designed a retail experience that blends fashion and contemporary art within Hudson Yards. Their design features a suite of polished fitting rooms, which we fabricated using thermoformed solid surface material.

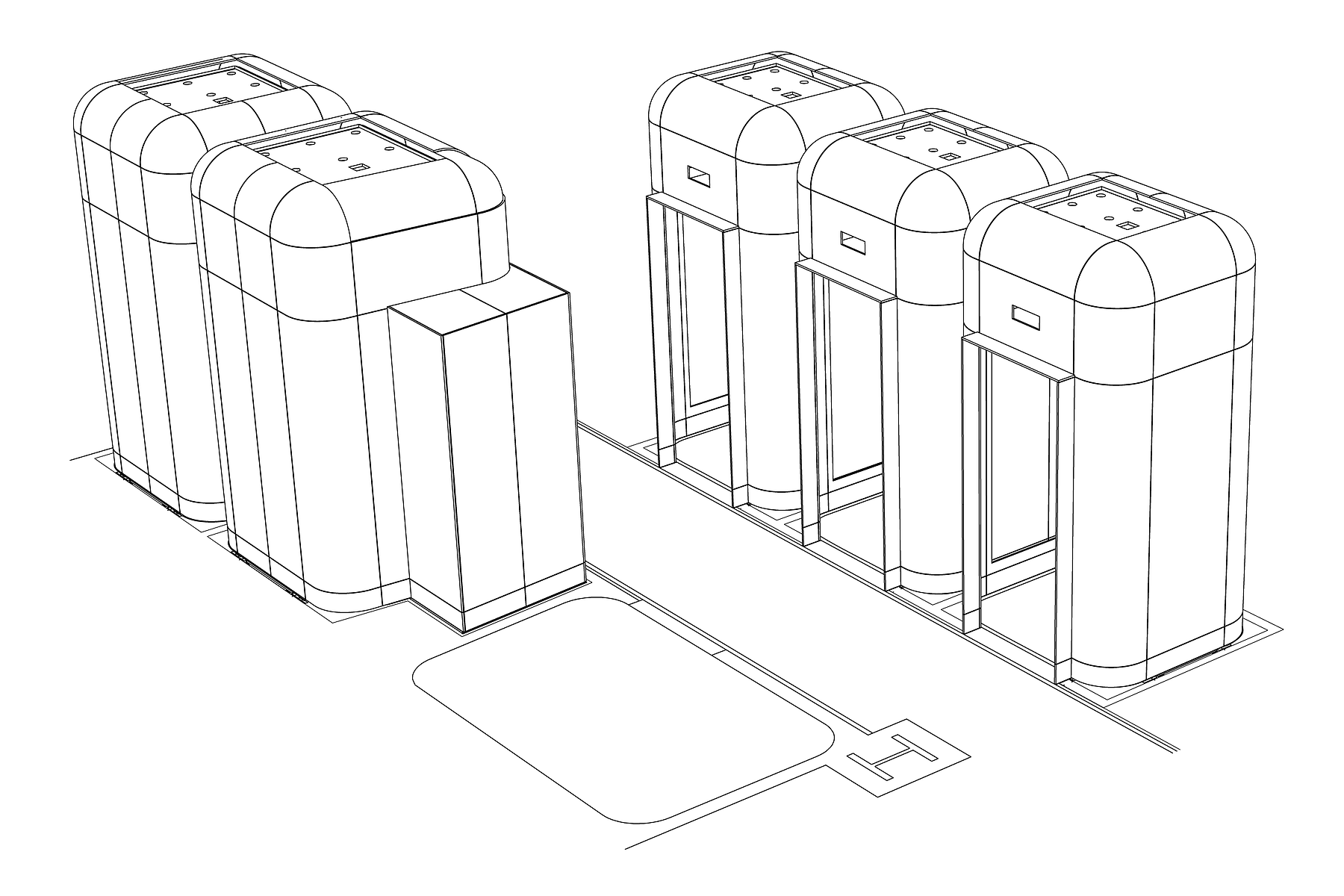

The 10-foot-tall fitting rooms are entered through a corridor with metallic finishes, mirrors and velvet curtains. The walls of each room are curved at the corners and bend into the ceiling to create pod-like spaces with accent lighting running along the floorline. This rounded design is composed of tightly spaced panels with narrow gaps that align with doorways and built-in mirrors. In total, our scope included five individual fitting rooms—three sharing the same geometry and two larger, distinct rooms, including one with ADA accessibility.

In such a curated environment, the details were extremely important. And, unlike some of our other projects, the designers approached us with an exact vision for the quality of space and materiality. Our biggest challenge was to achieve those qualities in the finished work. In particular, the specific blue color intended for the wall and ceiling surfaces was not available in an off-the-shelf product. Our team worked directly with the solid-surface manufacturer to develop a custom hue that would retain its vibrancy and sheen through the thermoforming process.

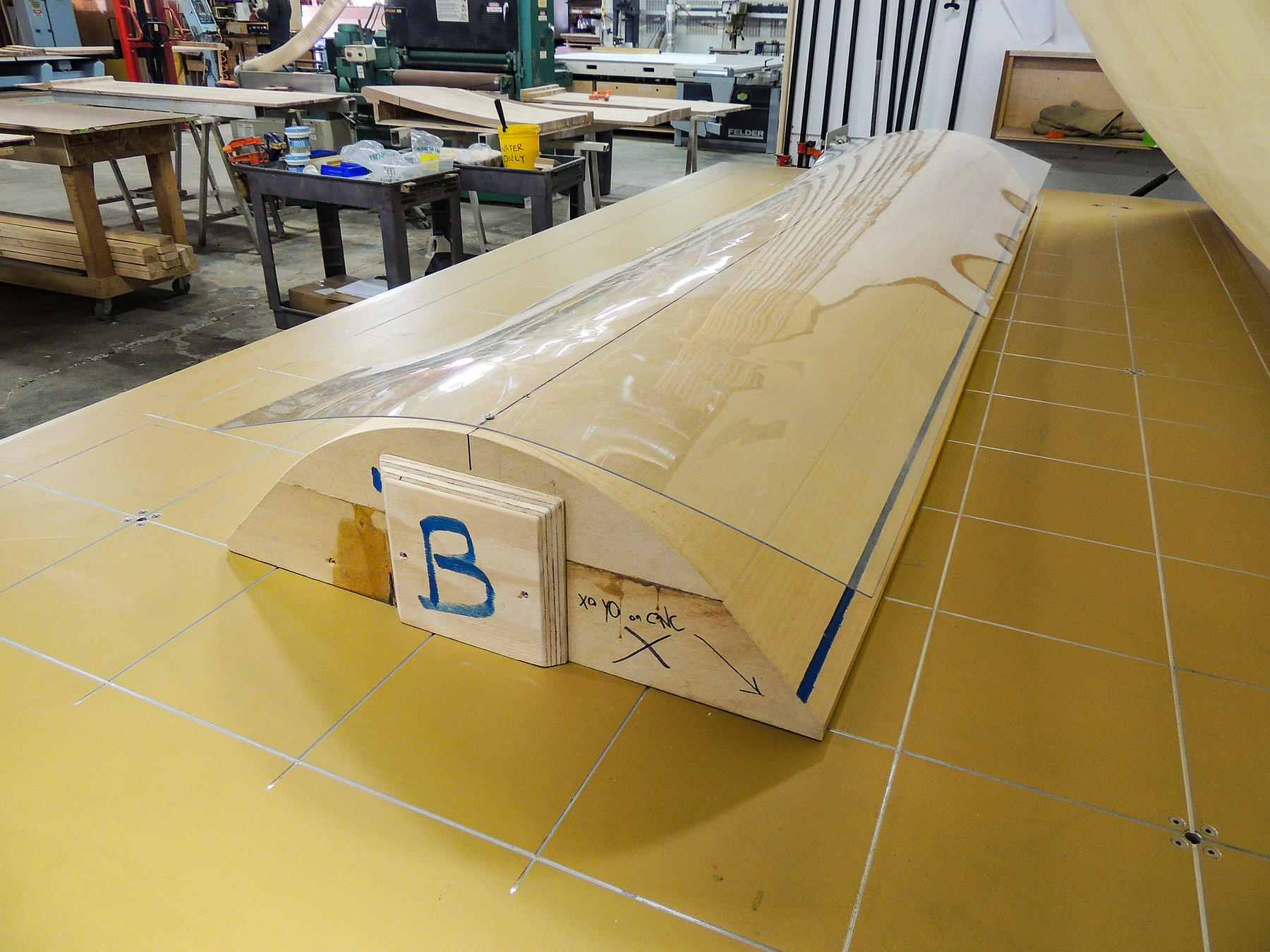

With the raw material in hand, we produced a series of armatures to use as molds in forming the various types of panels needed for each room. We used three basic typologies: flat panels, quarter-pipes and spherical octants or “shoulder caps.”

The flat sheets of solid surface material were heated until pliable and then draped over the armatures, which had to be design-engineered to avoid any buckling or tearing. Once the panels cooled, we transferred those to a set of corresponding jigs that stabilized the panels so they could be trimmed to their final dimension on our CNC-router. Having both a large format thermoformer and 5-axis CNC in house allowed us to quickly leverage both machines to keep the project on schedule. This digital approach also made it possible to precisely integrate built-in mirrors, custom hardware, fire safety equipment and lighting.

During an initial mockup phase, the designer and client decided on a custom high-gloss finish. After the machine processes were complete, we carefully hand-polished all of the surfaces. Our fabricators developed a specific technique that went beyond the manufacturer’s specifications to produce a consistent and durable finish.

Finally, we supervised the installation on-site. Since there isn’t access to the other side of the walls that these panels attach to, we revised connection details to include a z-clipped mounting system that allowed for ‘blind’ installation without having to use visible fasteners.

Ultimately, we were able to fulfill the client's vision for the fitting rooms as a polished and immersive extension of the brand. Since the design quality of fitting rooms is so often overlooked, we were excited to take on these custom features which resulted in a holistically designed retail experience.

Client

Architect

Location

New York, NY

Completion

2019

Photography

SITU