GIRI

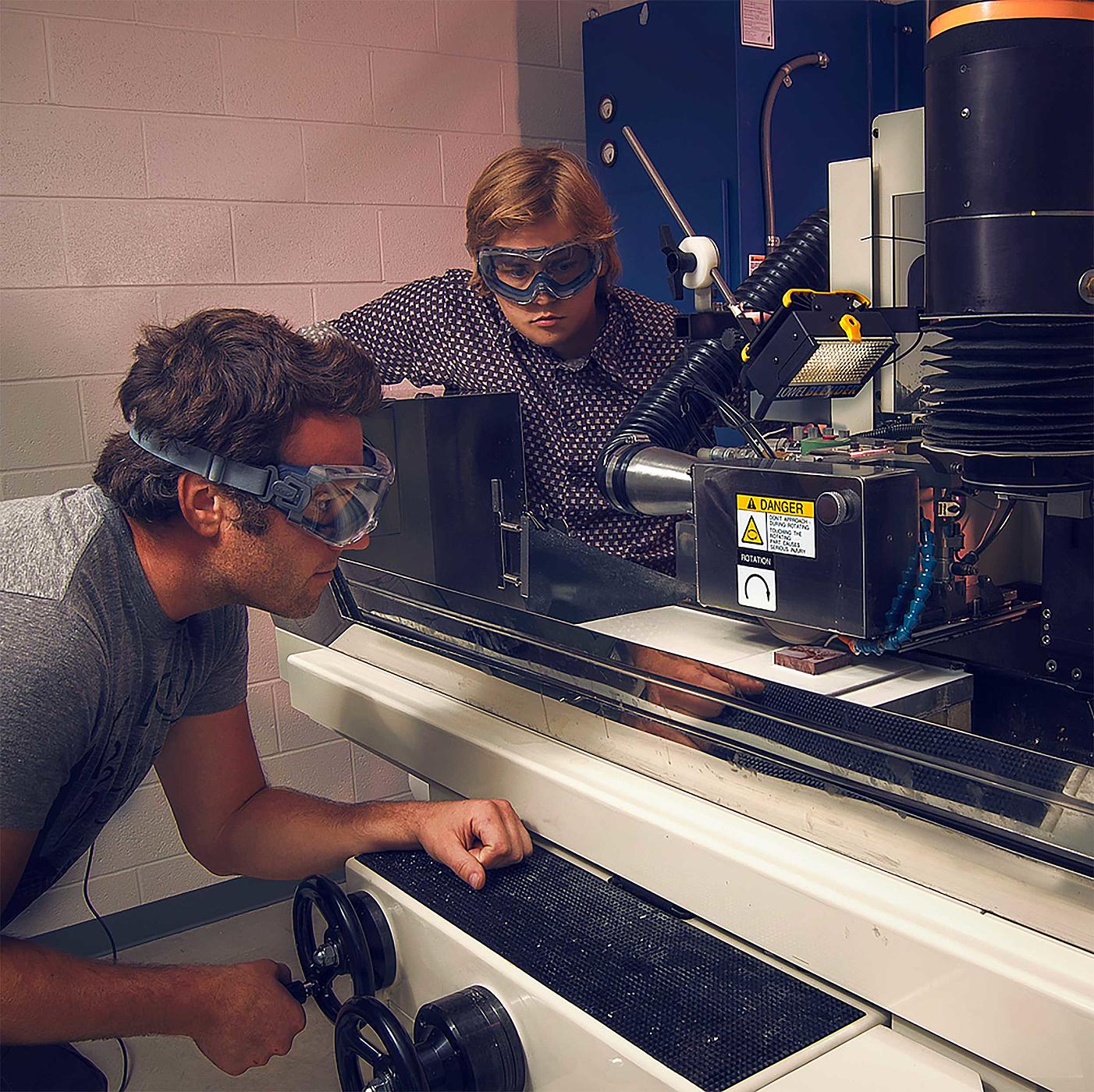

GIRI (Grinding Imaging and Reconstruction Instrument) was designed and built to process physical specimens and generate 3D digital models of objects embedded in materials such as rock and metal.

Learn more about GIRI here:

http://giri-inc.com/

The CNC-based instrument runs an automated routine of grinding and imaging, allowing researchers to analyze samples at a greater volume and frequency than ever before. The process reveals successive layers (serial sections) of the sample while creating a permanent digital archive of the images, which are then turned into a digital model. Models can be used for hydrodynamic simulation, morphological analysis, and a variety of other computational simulations.

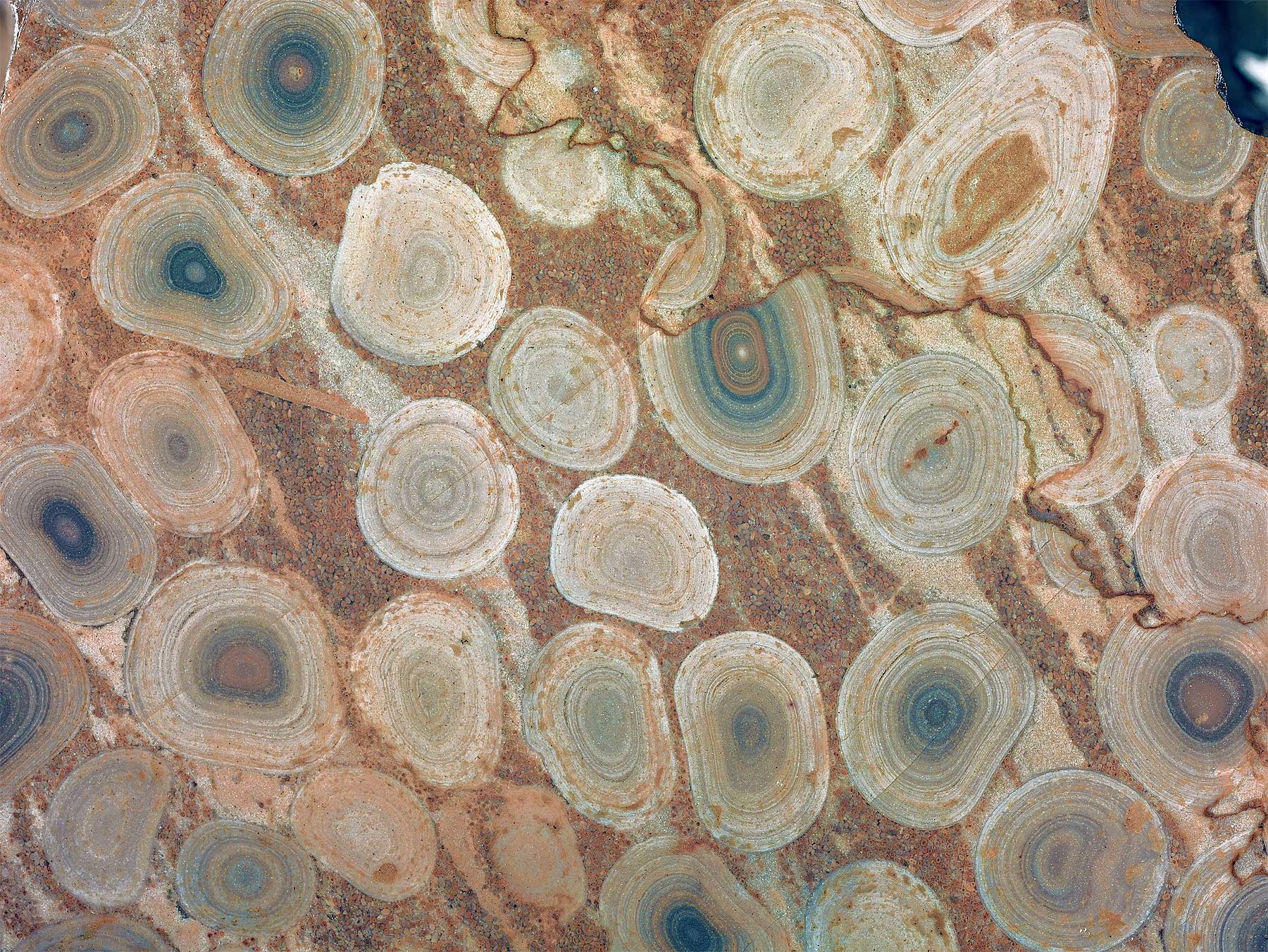

After collaborating with Princeton University Geologist Adam Maloof on the Trezona Fossil reconstruction project, SITU received grant funding from the National Science Foundation (NSF) to develop an instrument that would section and image not only fossil specimens, but any sort of dense material which might conceal precious objects buried within. GIRI, the outcome of this research, is a contemporary iteration of a simple serial sectioning instrument that grinds away layer after layer of sample, revealing and in this case recording, sequential cross sections which can subsequently be used to reconstruct and model features of interest.

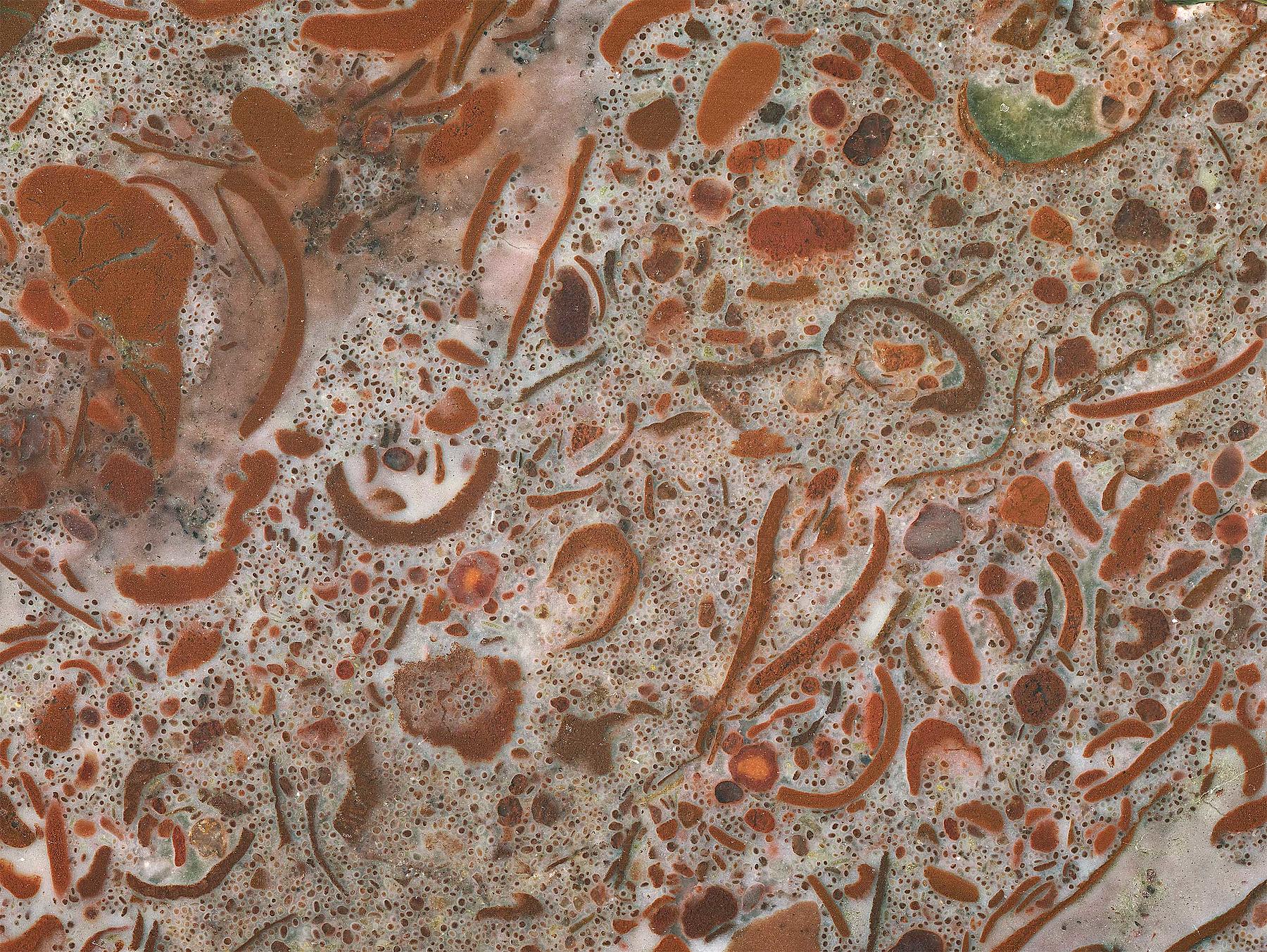

In order to record these cross sections, SITU integrated a DT RCam—a medium format 80 megapixel camera—directly onto a CNC precision grinding machine. This ultra-high resolution reprographic camera, equipped with vibration reducing leaf lens technology, is normally used to archive precious library collections, and in this case allows GIRI to image serial sections in 48 bit color with detail as fine as 5 microns (see images above). Optical targets such as the one shown in the image below were used to measure the camera sensitivity. The same methodology is used when calibrating satellite cameras.

As opposed to other computed tomography (CT) technologies such as X-ray based CT, GIRI excels at identifying embedded objects with little to no density contrast and at a greater volume, allowing for the imaging of exceptionally large heterogeneous samples, up to 20,000 cubic cm, with finer resolution than particle accelerating synchrotron based methods. While these non-invasive methods might be preferable when examining precious samples, the results of GIRI's destructive technique are unmatched in precision and cost.

Central to GIRI’s utility is the ability to model the specimens using three dimensional pixels called voxels. Unlike points and polygons which are used in a coordinate based system to define a shape’s surface, voxels represent an object’s matter at any given point, interior and exterior, much like how a pixel describes every point of light for 2D representations. This means that while a polygonal model would be great at describing a 3D structure with empty or homogeneously filled interior space, a voxel model excels at representing the materiality of a heterogeneously composed structure, perfect for anisotropic objects embedded in solid matter.

Such precise capabilities greatly exceed the utility of surface mesh modeling commonly employed by 3D modeling software and may have interesting implications for architects and designers who might begin gearing their consideration of 3D modeled objects towards that of a solid whole. For a look into the capabilities of the voxel modeling software GIRI uses, check out the video below.

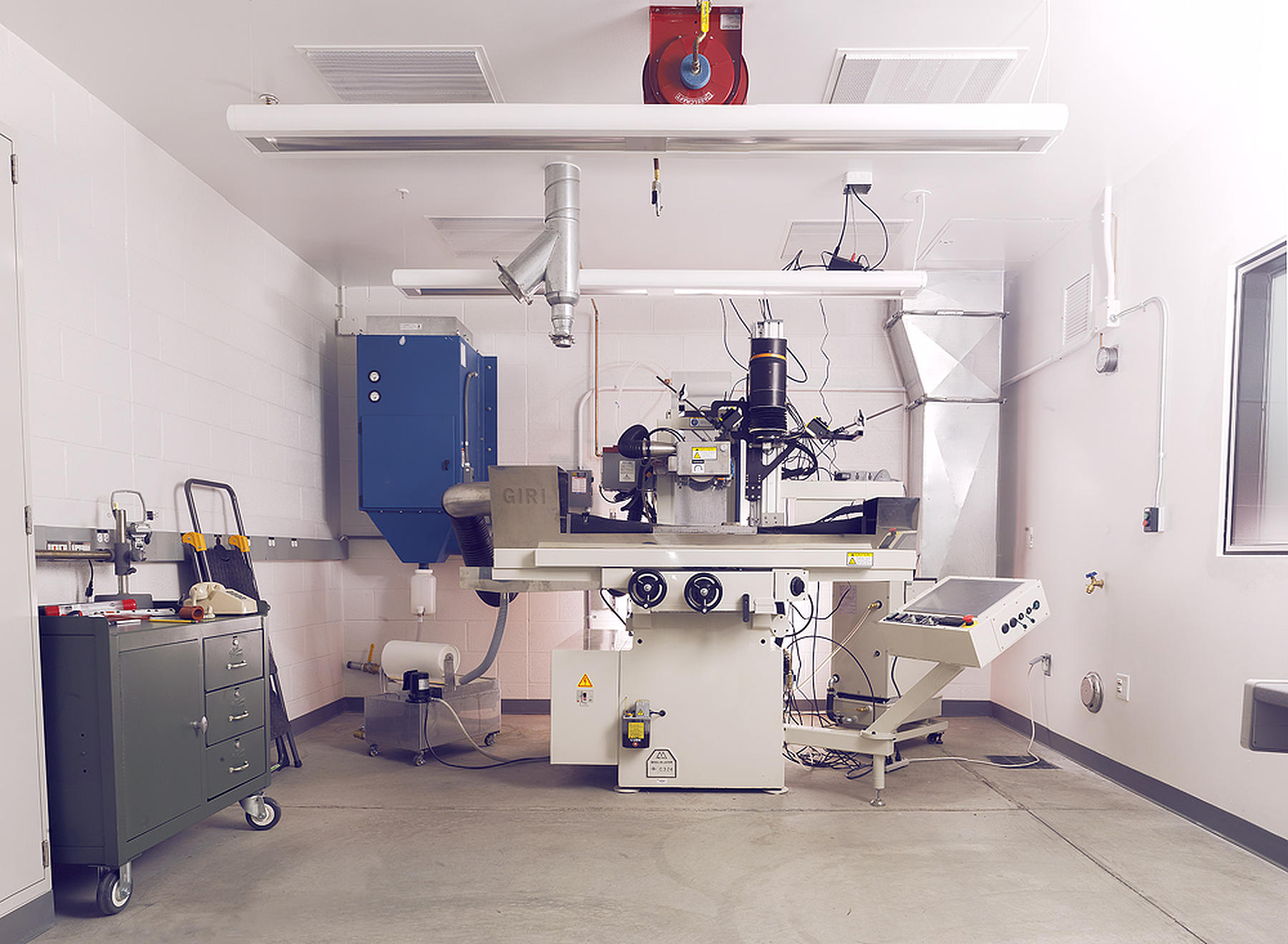

Due to the wealth of research opportunities this machine enables, Princeton University has made the first GIRI machine the centerpiece of its newly constructed, freestanding Grinder Laboratory, seen below. The lab welcomes interdisciplinary collaboration and is interested in studying materials ranging from fossil bearing limestones to meteorites to petroleum reservoir rocks to fuel cells to concrete to building materials and even metals. Over the coming year Dr. Maloof will be working to explore the full range of potentials that GIRI has to offer.